Figure 4 (DLP)

Figure 4: Digital Light Processing (DLP)

Figure 4 (DLP) 3D Printing/Additive Manufacturing is an ideal process for a variety of application needs such as functional prototyping, direct production of end-use parts, moulding and casting, and includes rigid and durable thermoplastic-like, rubber-like, heat resistant and biocompatible capable materials.

This direct 3D production allows for up to 10,000 parts to be manufactured per month. Formero has the capability to run different materials and different jobs at the same time using multiple printers.

Figure 4 solutions deliver accurate parts with six sigma repeatability in a diverse range of robust, production-grade materials for immediate part turnaround without the costs and delays of tooling. Figure 4 platforms are ideal for fast product iteration, mass-customisation, bridge manufacturing and low-volume production.

Materials Available.

Figure 4® Pro Black 10

Production-grade additive manufacturing material with game-changing thermoplastic-like mechanical properties and long-term environmental stability.

Figure 4® PRO-BLK 10 delivers on the promise of additive manufacturing with true direct digital production of plastic parts. Go from CAD to manufacturing line in one day with tool-less, same day part production.

With a fast print speed and simplified post-processing that includes a single curing cycle and single solvent cleaning, this material delivers exceptional throughput. It is a high precision resin producing parts with a smooth surface finish and sidewall quality, and has excellent mechanical properties and long-term environmental stability that brings a new level of assurance to 3D production.

Applications

- Tool-less, same day production

- Direct production of small black plastic parts such as motor housings, connectors, snap-fits, automotive interior and other general-use parts

- Digital production to replace injection moulding or soft tooling processes

Benefits

- Improved environmental stability of mechanical and performance properties over time

- Excellent surface quality and repeatability

- Accurate, low distortion material

Features

- 70°C heat deflection temperature

- Durability and strength

- Biocompatible capable per ISO10993-5 and ISO10993-10

- Exhibits thermoplastic behaviour in necking at tensile break point

Technical Specs

| Tensile Strength: | 63 MPa |

| Elongation at Break: | 12% |

| Flexural Strength: | 92 MPa |

| Impact Strength: | 24 J/m (notched Izod) |

| Colour: | Black |

| Build Size: | 124.8×70.2×346 mm |

| Layer Thickness: | 0.04 mm |

For more technical data download the material data sheet.

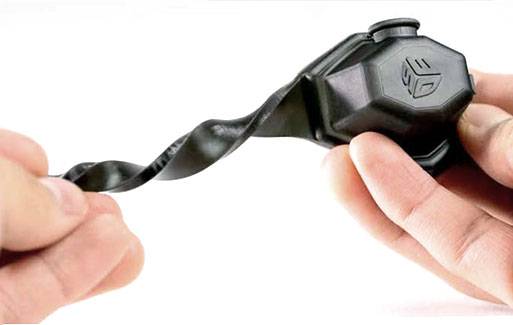

Figure 4® Rubber-65A Black

A mid-tear strength, production-grade rubber combined with Shore 65A hardness and a high elongation at break.

Figure 4® RUBBER-65A BLK material is specially formulated to address key customer needs for rubber parts featuring production performance properties and production mechanical properties tested according to industry standards.

Figure 4® RUBBER-65A BLK is a mid-tear strength, high elongation at break, Shore 65A material for the production of medium hard rubber parts with slow rebound, for applications such as grips, handles, gaskets, bumpers, seals, vibration dampening components and more.

Applications

- Air/dust gaskets

- Seals and housings

- Vibration dampener and pipe spacers

- Bumpers

- Grips and handles

Benefits

- Production performance properties

- Long-term stability

- UL94 HB flammability test standards

Features

- Biocompatible capable per ISO 10993-5 and ISO 10993-10

- High elongation at break

- Shore-A of 65 (medium hard rubber)

- Mid-tear strength

Technical Specs

| Tensile Strength: | 5 MPa |

| Elongation at Break: | 126% |

| Colour: | Black |

| Build Size: | 124.8×70.2×346 mm |

| Layer Thickness: | 0.04 mm |

For more technical data download the material data sheet.

Figure 4® High Temp 150C FR Black

UL94 V0 rated flame-retardant black plastic with >150°C heat deflection temperature.

Figure 4® High Temp 150C FR Black is a rigid, flame-retardant black material that can be used for production parts requiring UL94 V0 rating as well as FAR 25.853 and 23.853 capability. It provides long-term environmental stability with an injection moulded-like surface quality.

This material is recommended for consumer, transportation, and aerospace applications that require performance at high temperatures like brackets, covers, and circuit board housings and covers.

Applications

- Printed circuit board covers

- Electrical and under-hood housings requiring UL94 V0 rating

- Rigid covers, hangers, and brackets

- Small FAR 25/23.853 in-cabin parts

- Flame retardant parts for trains and busses

Benefits

- Self-extinguishing, flame-retardant material

- Halogen-free

- High heat deflection temperature for demanding applications

- Excellent surface quality, accuracy and repeatability

- Capable of plating and painting

Features

- Passes UL94 V0 test standards @ 2mm and 3mm thickness

- Passes FAR Part 25.853 @ 12 second vertical burn and HB testing @ 3mm

- Passes FAR Part 23.853 @ 12 second vertical burn and HB testing @3mm

- Passes UL 746C GWIT and GWFI @ 2mm and 3mm thickness

> 150C @ 0.455 MPa HDT - Long-term indoor and outdoor environmental stability of mechanical properties

Technical Specs

| Tensile Strength: | 58 MPa |

| Elongation at Break: | 4% |

| Flexural Strength: | 100 MPa |

| Impact Strength: | 10 J/m |

| Colour: | Black |

| Build Size: | 124.8×70.2×346 mm |

| Layer Thickness: | 0.04 mm |

For more technical data download the material data sheet.

Frequently Asked Questions (FAQ)

DLP boasts rapid production capabilities, coupled with high precision and intricate detailing. These attributes position it as a favoured option for crafting precise prototypes. Notably, DLP substantially diminishes lead times and facilitates swifter design iterations.

Yes, DLP holds the capability to create parts featuring production-grade attributes such as refined surface finish, textures, dimensional accuracy, and notable mechanical performance. This versatility renders it suitable for a range of end-use applications.

DLP is compatible with an array of materials, encompassing engineering plastics and elastomers. This versatility in material options empowers the production of parts showcasing a wide spectrum of mechanical properties and functional capabilities.

Certainly, DLP thrives in crafting intricate and delicate designs with remarkable accuracy and resolution. Its ability to deliver a smooth surface finish and excellent sidewall quality further enhances its suitability for such tasks. The layer-by-layer methodology of DLP ensures the precise replication of even the most intricate details.

DLP serves a variety of industries including automotive, healthcare, aerospace, concept models, and consumer electronics. Its adeptness in producing intricately detailed and functional parts addresses a broad spectrum of requirements within these sectors.

No, there is no difference between Digital Light Processing (DLP) and Figure 4. The term “Figure 4” was coined by 3D Systems, the developer of the Figure 4 systems Formero has deployed. Both names pertain to the same additive manufacturing process, employing a UV light source to selectively cure liquid resin layer by layer, resulting in the fabrication of intricately detailed and precise 3D objects.

The timeline for DLP projects is influenced by factors such as part complexity, size, post-processing requirements, and the quantity being produced. DLP is notably swift in comparison to other processes and can frequently result in the completion of small geometries within hours, rather than days.

Ready to speak with us?

If you have questions please feel free to contact us.