Case Studies

Project Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

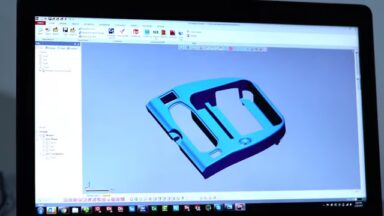

Read MoreAtom Industries – Leaf Blower

See how Formero’s 3D Printing Technology helped Atom Industries, an an innovative leader in the development and manufacture of lawn and garden equipment, improve their leaf blower’s design and performance.

Read MoreEmirates Uses SLS 3D Printing For Supply Chain Efficiency

With a fleet of over 252 aircrafts, Emirates airlines saw cost saving opportunities through lighter weight parts, reduced inventory, and a more efficient supply chain using 3D printing technology.

Read MoreToyota Racing Car SLS Prototypes

Aussie Racing Cars were only a week away from the deadline of completing their new scaled-down Toyota Aurion racing car when they contacted Formero for assistance.

Read MoreMedical Device Prototypes

Using SLA we printed master models, in conjunction with silicone tooling & vacuum casting, to produce polyurethane prototypes for Lymphease, a patented medical device for the self administered treatment of Lymphoedema.

Read MorePrototypes For Packaging Design Validation

Using SLA technology, we built a one and two-piece prototype for the Birdstone design team in a rigid and tough clear plastic material offering clarity and transparency.

Read MoreNew Bottle Design

Schweppes enlisted Birdstone, a Melbourne, Australia based packaging agency to design a contemporary look for their sparkling waters and carbonated soft drinks.

Read MorePrototypes for a new-look bottle design

When James Boag wanted to change the look of their premium larger product, glass bottle supplier, Orora, needed to find the most effective solution which didn’t involve a complete overhaul of their existing tooling and manufacturing systems.

Read MoreQUICKCAST™ Patterns

Showcasing how we helped Vaupell create metal parts more efficiently using QuickCast, a technology that creates a ceramic mould from a 3D printed wax pattern.

Read More3D Printed Drone Camera Mounts

3D printing reduces development cycles and allow designers to be more agile and iterate quickly with prototypes used for form, fit and function testing.

Read MoreHigh-tech Drones for Defence & Energy Sectors

Using MJF Technology Freespace Operations were able to evolve their Callisto 50 Multirotor autonomous modular & multipurpose industrial drone much faster and provide a low volume production alternative.

Read MoreRopes Edge Additive Manufacturing

Ropes Edge is an American start-up company dedicated to supplying innovative safety equipment that protects rope from hazardous abrasive edges used in rescue and rigging systems.

Read MoreMaton Guitars Integrating Additive Manufacturing Technology

Established in the early 1940’s, Maton is Australia’s longest running and most successful guitar manufacture. Here is how they are using Additive Manufacturing in their business.

Read MoreZoetrope Based on Cuphead Videogame

Designed by Megafun using the charming and cheeky animated characters of Studio MDHR’s Cuphead videogame, the zoetrope required 270 detailed models for ACMI motion picture exhibition.

Read More