3D Printing & Additive Manufacturing

Limitless 3D Printing

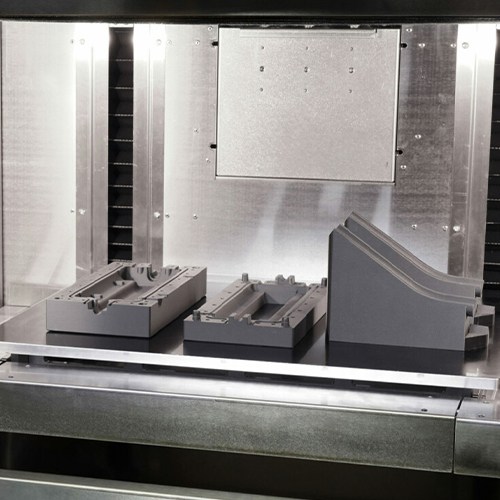

As Australia’s largest and most advanced 3D Printing & Additive Manufacturing Service Bureau, we are committed to bringing your ideas to life with speed and efficiency. When you choose Formero, your projects will take shape in our state-of-the-art printing lab located in Melbourne, Victoria.

At Formero, we feature the most comprehensive in-house capability with 12 distinct 3D printers spanning 6 advanced technologies. This diversity allows us to cater to a wide range of projects, whether you’re in aerospace, healthcare, or any other industry. With over 20 materials at our disposal, we can transform your concepts into reality using the ideal material for your requirements.

From rapid prototyping to additive manufacturing processes, our expertise in 3D printing is unparalleled, spanning across limitless commercial and industrial applications. Our team’s dedication to precision and craftsmanship ensures that your creations are handled with the utmost care.

Benefits of 3D Printing with Formero.

Customisation

Tailor your products to specific requirements, offering personalised solutions for your projects.

Cost-Effective

Reduce production costs by eliminating the need for complex tooling and moulds, especially for low-volume or custom designs.

Complex Geometries

Create intricate and complex designs that traditional manufacturing methods simply can’t replicate.

Speed and Efficiency

Shorten your development cycle with rapid prototyping, enabling faster iterations and reduced time-to-market.

3D Printing vs Additive Manufacturing.

The distinction between 3D Printing and Additive Manufacturing is primarily defined by the quantity of parts involved. The term 3D Printing is more often used when printing in smaller batches, typically around 1-20 prototypes, offering a precise and swift solution. Additive Manufacturing, on the other hand, steps in for larger production needs, ranging from 100-200 parts. This additive manufacturing process is the opposite of subtractive manufacturing – which works by cutting out part of the material to create the final product. Additive manufacturing is often associated with SLS, MJF, and DLP technologies, showcasing its capacity to meet substantial manufacturing requirements.

Rapid Prototyping

At Formero, we understand that in today’s fast-paced business landscape, time is of the essence when bringing your ideas to life. Specialising in Rapid Prototyping, we can quickly transform your concepts into tangible prototypes using cutting-edge 3D Printing technologies and traditional Vacuuming Casting techniques. Our team of highly experienced and skilled manufacturers are dedicated to precision and efficiency, streamlining Rapid Prototyping from concept to reality.

We pride ourselves on a collaborative approach with our customers, and we are committed to helping your Rapid Prototyping project be successful.

Whether you’re a start-up testing a new concept, an established business launching a ground-breaking product or wanting to test new products on existing factory processing equipment, Formero is your trusted partner for Rapid Prototyping.

Ready to speak with us?

If you have questions please feel free to contact us.

Frequently Asked Questions (FAQ)

While STL stands out as the standard for 3D Printing, we can also handle a variety of other 3D formats. These include IGS/IGES, STP/STEP, Parasolid ACIS, Solidworks, OBJ, VRML, FBX, among others.

Currently, we don’t provide internal design services. If you require aid in crafting a 3D CAD model for your concept, kindly reach out via email. We will furnish you with the contact details of design firms experienced with our procedures.

All 3D Printing conducted by Formero takes place at our state-of-the-art printing facility in Nunawading, Victoria. We boast an extensive array of cutting-edge technologies and materials, setting the industry standard in Australia. Our facility is equipped with 12 professional and production grade printers and dozens of material choices.

You can quickly acquire pricing information using our online quoting system. If you require guidance or would rather communicate with a member of our team, please feel free to reach out via email at sales@formero.com.au or give us a call at +61 3 8899 7280.

Yes, we can ship orders anywhere in the world. Please contact our team for a shipping cost.

With our 3D Printing service, you have the option to order as few as 1 item. The advantage of utilising 3D Printing, especially for prototyping, is its capacity to cater to your requirements regardless of the quantity needed.

The lead times vary based on the specific technology, material, and post-processing preferences for each job. For instance, a basic SLS or MJF part can be manufactured in as little as one to two business days.

We provide a selection of more than 20 diverse materials for you to choose from. If you’re uncertain about which material aligns best with your project’s specifications, our team is readily available to engage in a discussion and propose a material that will be suitable for your project’s requirements.

We handle a diverse array of confidential and proprietary information from both small and well-known clients on a daily basis. Rest assured, you retain ownership of your data. We solely utilise it for estimating, constructing, and reviewing projects tailored to your needs. Your customer data and part files are strictly kept within our services and aren’t shared externally. Our server and network housing the data are secured by a firewall, with access limited to authorised personnel only.

Yes, we provide a mutual Non-Disclosure Agreement that can be executed by both parties. If you require us to sign an NDA that you provide, please note that we will need to evaluate it before signing, and this evaluation process may take a few days.

For rapid prototyping projects we typically utilise 3D Printing and Vacuum Casting. These techniques ensure precision, a wide range of materials and speed in transforming your concepts into tangible prototypes. The 3D Printing technologies we use are SLA (Stereolithography) and DLP/Figure 4.

The turnaround time for your prototype depends on the complexity of the project and the chosen rapid prototyping method. Generally, we strive for efficient timelines, with some projects completed in a matter of days. Our team works closely with you to understand your rapid prototyping requirements and optimise the production process to meet your specific needs. Our 3D Printing and Vacuuming casting services are 100% based in Melbourne, Australia. This reduces the timeline for all projects as we don’t reply on international shipping.