QUICKCAST™ Patterns

Aerospace QuickCast™ Pattern

Traditional investment casting creating metal parts from a ceramic mould after a wax pattern has been burned away has been around for thousands of years. Over the last century, the process has benefited from many innovations, but creating this kind of tooling for complex parts is still slow and costly. Production time is typically measured in months and costs can run into hundreds of thousands of dollars.

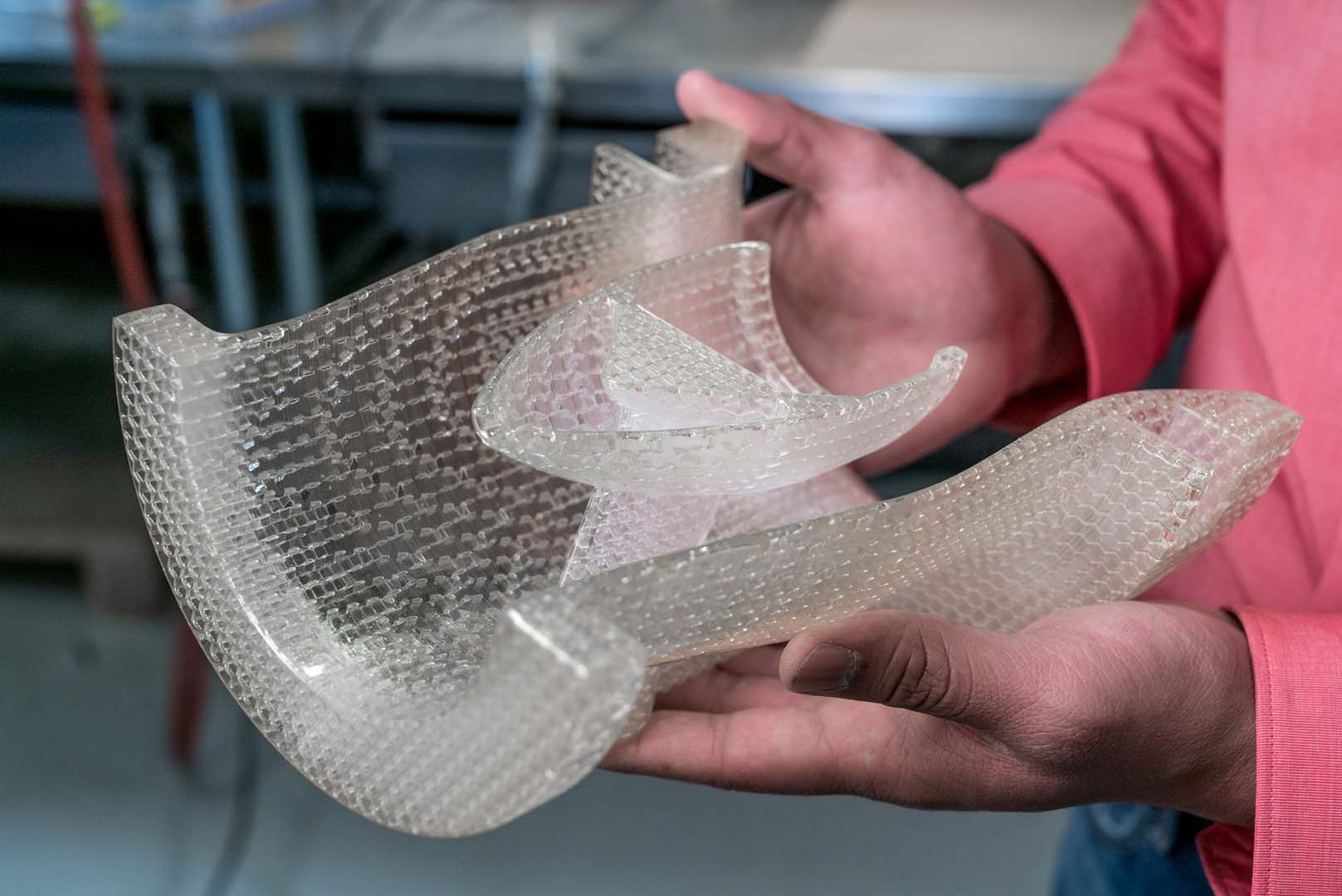

Vaupell, a supplier of aerospace components and subassemblies, is using QuickCast™. A 3D printing build style that consists of a hollow SLA pattern with an internal hexagonal support structure. The structure adds strength to the pattern and facilitates the collapse of the pattern during the investment casting process. It’s also a fraction of the cost of traditional methodologies.

The QuickCast™ process from 3D Systems is ideal for the aerospace market, which often requires low volumes of highly complex parts.

Large, accurate builds

Andy Reeves, a Vaupell sales engineer for new business development, estimates that a specific 66cm diameter part pattern can be produced with QuickCast™ on a 3D Systems large 3D printing platform in three days for less than $15,000. In comparison, a wax tool for the same part could take several months at a cost of $200,000 plus.

The accuracy of the QuickCast™ parts (0.025-0.05 mm) enables Vaupell to meet the exacting requirements of its aerospace customers. We’re saving time on the post-print finishing because the finish of the resins is good.

Meeting market needs

Reeves says the market for QuickCast™ investment casting stems from two compelling business needs: creating castings for parts that cannot be tooled in any other way, and creating castings for parts that are so complicated it would take up to a couple of years to deliver a production- worthy mould.

Aerospace companies have discovered that 3D printing can enable complex designs that allow them to reduce the number of parts in an assembly and lower weight while maintaining the same or greater strength and durability.

The need for production-worthy patterns from moulds that would take long periods of time to design and produce in wax has created a substantial bridge- tooling business for Vaupell’s rapid prototyping division. QuickCast™ patterns enable our customers to get a part long before a production or prototype tool could be designed, made, tested and brought online, says Wong.

Wong cites one project where Vaupell used QuickCast™ to create a complex investment casting pattern and produce 20 parts in a matter of days, scaling quickly to 120 parts a month. The customer wouldn’t have been able to fulfil the contract if we didn’t use QuickCast™ to deliver the parts. Sometimes we produce 150 pieces of two or three QuickCast™ patterns a month over the course of a year while the customer is still developing and building wax tooling.

Better burnout

A major concern around investment casting in the early days of 3D printing was the quality and properties of available materials. That concern has been eliminated with the release of new materials that burns out with lower ash content. If resin is unable to burn out completely, the customer is going to have an issue, says Wong. The complete burnout and cleanliness of the burnout are definitely keys to quality.

Reference: 3D Systems QuickCast™

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

Project Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

Read MoreAtom Industries – Leaf Blower

See how Formero’s 3D Printing Technology helped Atom Industries, an an innovative leader in the development and manufacture of lawn and garden equipment, improve their leaf blower’s design and performance.

Read More