3D Scanning for Training Simulation

REALISTIC VR PILOT TRAINING SIMULATION

The KA350 King Air is a twin-engine turbo-prop aircraft based at RAAF Base, Sale, and is used extensively for training of Air Force Mission Aircrew and Navy Aviation Warfare Officers.

Challenge:

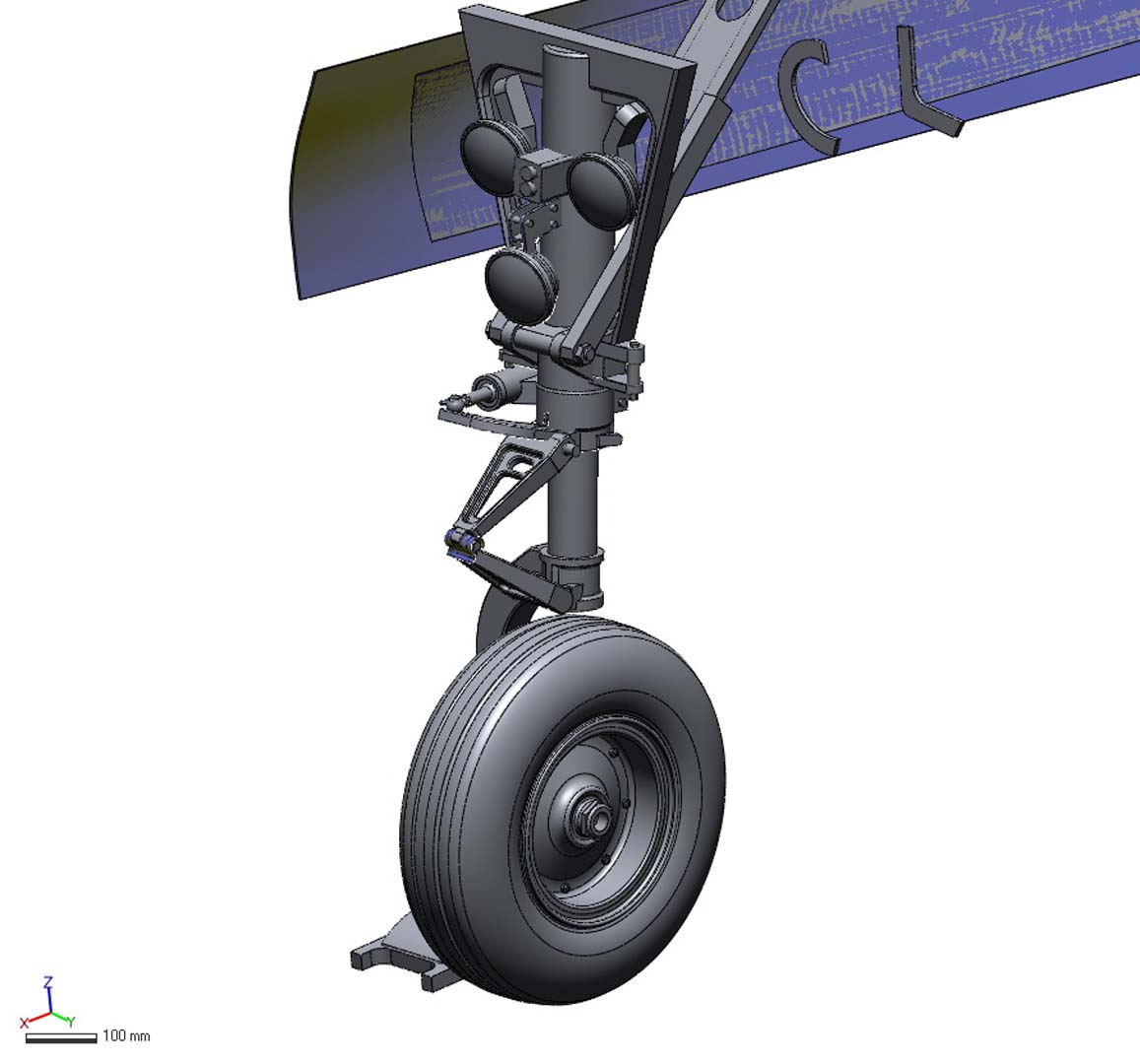

To better prepare each pilot for flight they have to pass a unique test involving aircraft faults. These faults are known as Foreign Object Damage (FOD) and simulate real world situations such as flat tyres, oil leaks, wasp nest in fuel drain hole, or an open petrol cap. RAAF needed new training solutions with minimal disruptions to their general operations.

Solution:

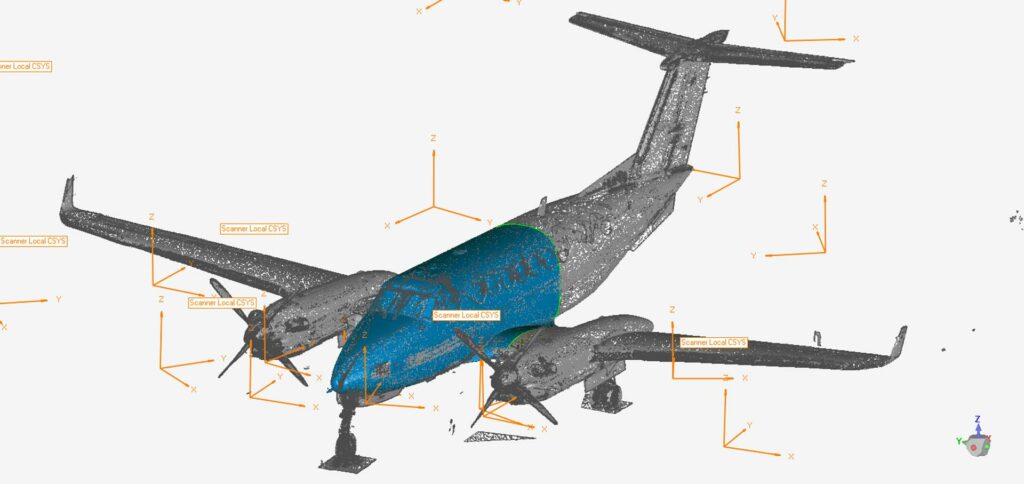

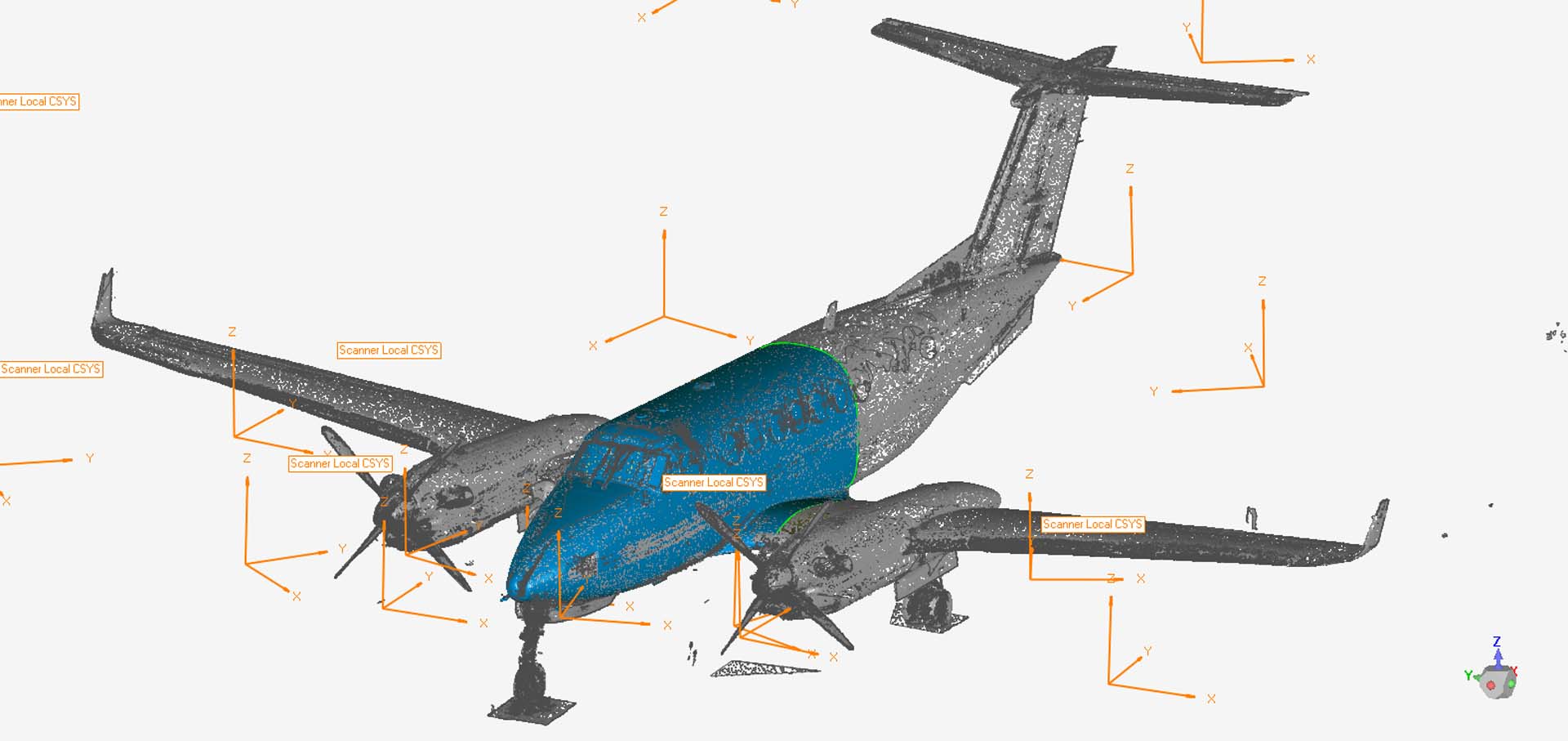

A Virtual Reality (VR) training simulation was proposed using a combination of 3D scanning and photogrammetry technology. Realistic digital twins were created that captured the colours and textures for a virtual world.

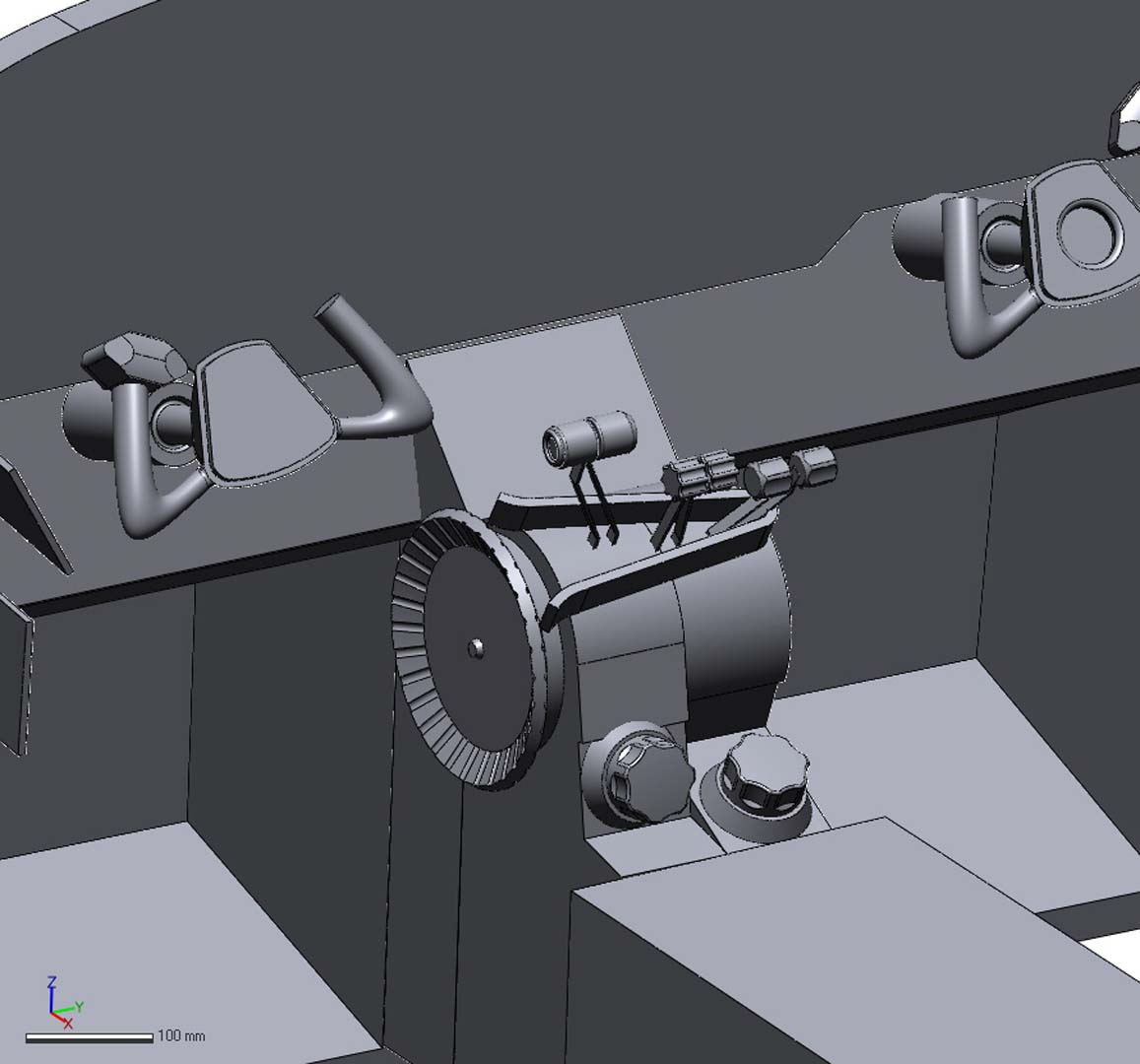

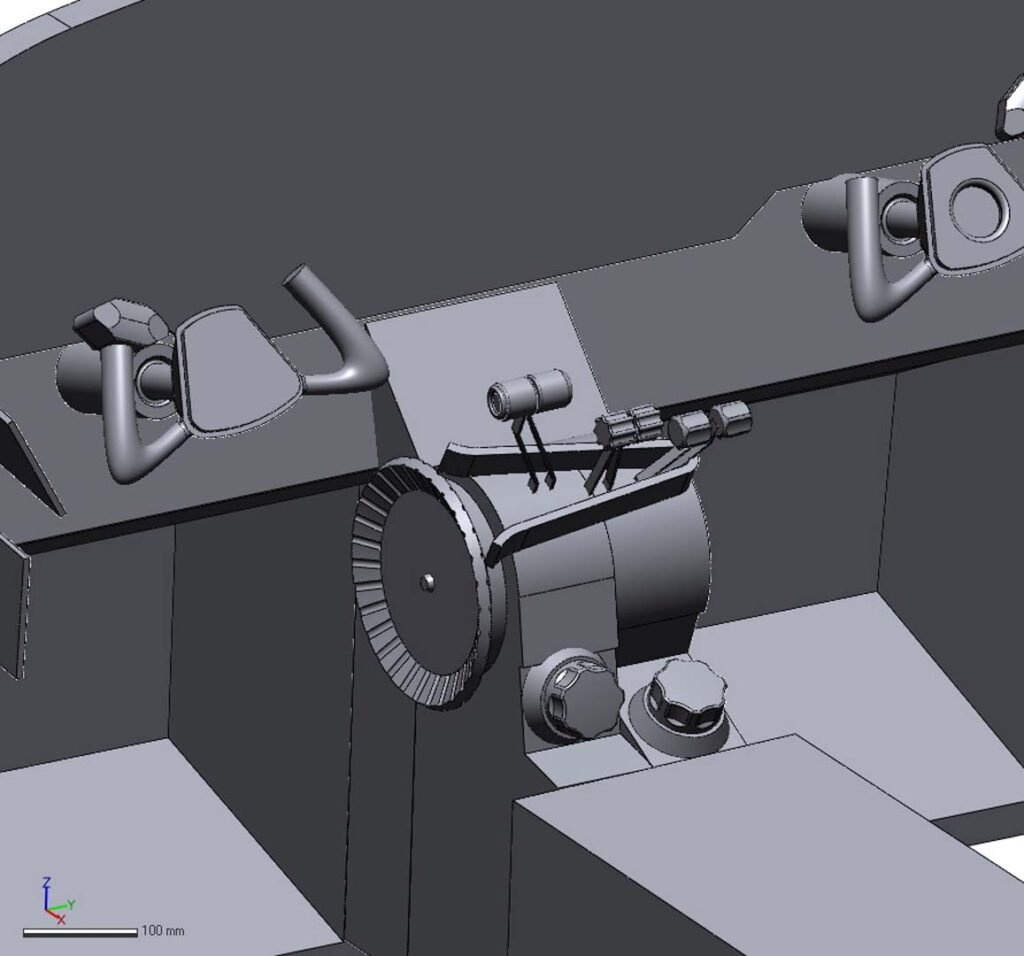

Each aircraft fault was physically recreated so it could be photographed and scanned using handheld and terrestrial scanners, as well as 360° array of high-resolution digital cameras. This was all done at night using professional lighting to minimise shadowing effects and achieve optimum results.

Within five days, our scanner operators obtained the necessary data, which was then processed so the aircraft geometries could be rebuilt as full-colour 3D digital (computer) models.

Result:

The data collected enabled the KA350 digital twin aircraft to be integrated into the Euclideon 3D VR platform. In total, it took 10 days to complete the project, from scanning the aircraft to delivery of the finished files.

Wearing VR glasses, pilots can interact with the digital plane, allowing the tester to select different scenarios the pilot has to overcome. RAAF has 700 pilots and each pilot needs 24 weeks of training to qualify. A VR training solution helps ensure pilots are properly trained in aircraft maintenance to minimise disruptions caused by aircraft on ground (AOG).

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

Project Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

Read MoreAtom Industries – Leaf Blower

See how Formero’s 3D Printing Technology helped Atom Industries, an an innovative leader in the development and manufacture of lawn and garden equipment, improve their leaf blower’s design and performance.

Read More