MJF 3D Printing vs Injection Moulding

August 3, 2022

Digital Manufacturing is changing the way we think about manufacturing as additive technologies, materials and processes mature.

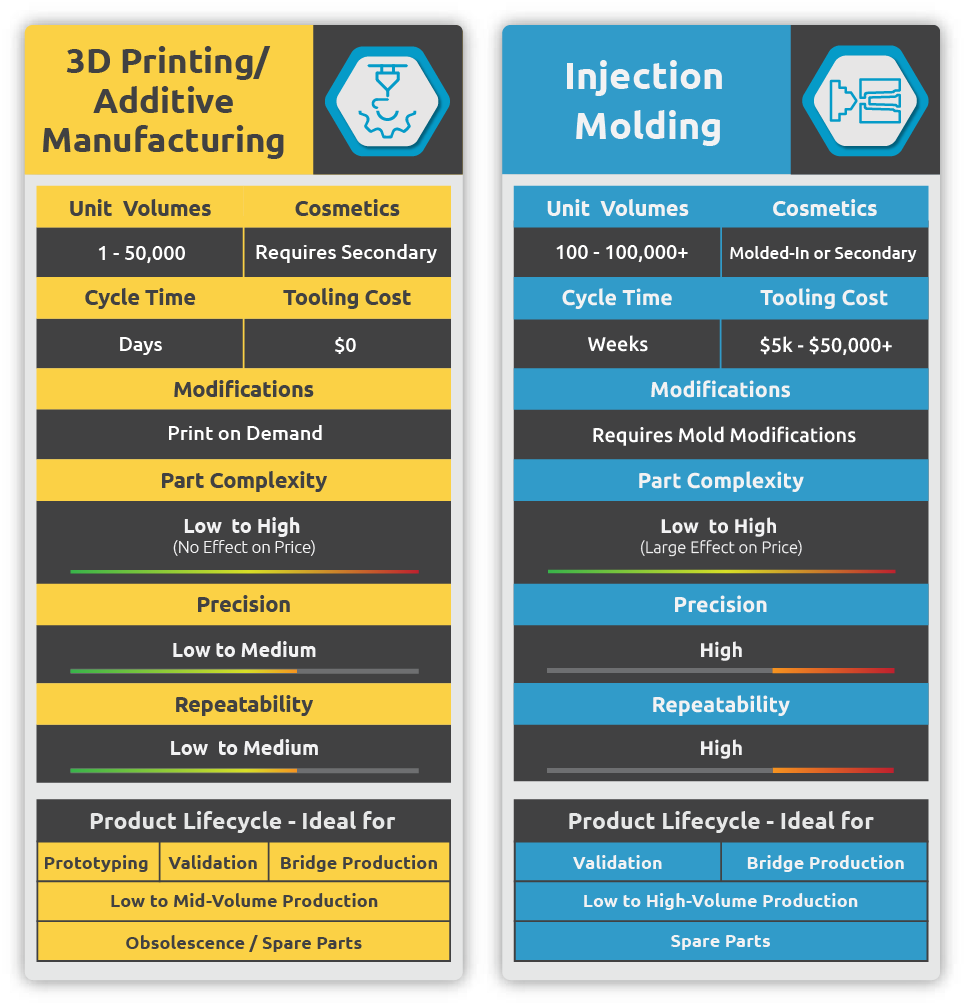

Injection moulding is regarded as the standard form of manufacturing technology for many plastic components and has been relied upon for many years. It’s a highly mature technology that businesses are very familiar with. Additive Manufacturing (AM) is causing companies to rethink manufacturing processes as they realise 3D printing isn’t just for prototyping. 3D printing is an ideal solution for small batches, complex parts that may require frequent design changes or customisation.

Injection moulding has limitations on design as constructing a mould constricts the geometry of the designs in several crucial ways. Discovering and rectifying any mistakes found in the moulding process will cost time and money. If a part turns out wrong, the mould needs to be completely remade, and chances are an entire batch of parts will need to be scrapped.

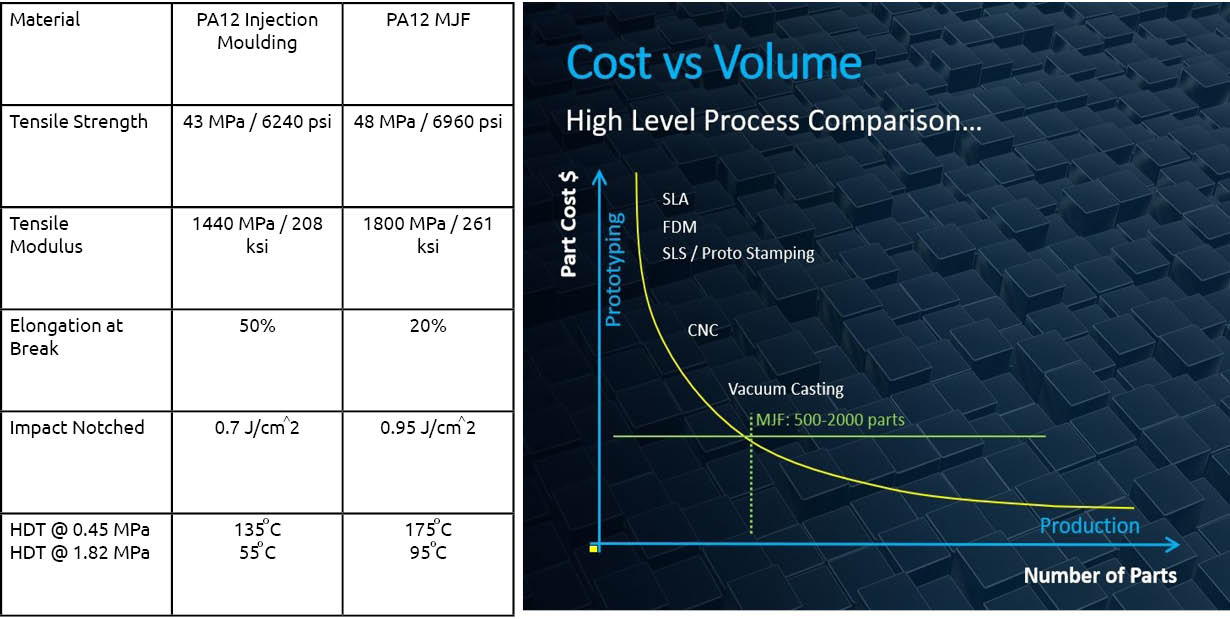

Material performance comparison (Injection Moulding vs HP’s Multi Jet Fusion MJF)

What is Multi Jet Fusion

HP’s Multi Jet Fusion (MJF) is an industrial 3D printing process used for the rapid manufacture of prototypes, and quality production parts. The end-use parts exhibit isotropic properties in all axes, which translates to consistent mechanical properties throughout the part. This results in as printed parts that require little post-processing, and parts exhibit many properties including vibration dampening, durability and water-tightness.

An MJF part is comparable to parts created by injection moulding and is stronger than components created by fused deposition modelling, which is why MJF technology is the 3D printing solution for functional parts in many industries.

Multiple build platforms and ISO-certified processes enable Formero’s MJF printers to run around the clock, 7 days a week. Whether it is one part or one hundred, MJF and Formero enable the production of end-use custom parts in your hands in as little as 2 days.

How does Multi Jet Fusion work?

An MJF printer uses an inkjet array to selectively apply both fusing and detailing agents across a bed of nylon powder. After that, heating elements fuse each layer into a solid, layer by layer until the parts are complete. Completed builds are then moved from the printer to a processing station to be cooled, recycling the loose powder for the next build. De-powdered parts are bead blasted to remove residual powder before post-finishing to customer specifications.