Atom Industries – Leaf Blower

Fit And Function Prototype

Challenge

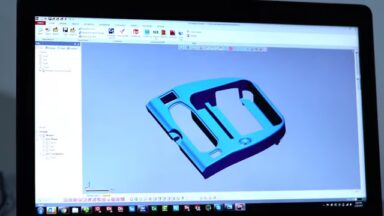

Atom Industries is an innovative leader in the development and manufacture of lawn and garden equipment. Whilst Atom had previously utilised traditional 3D printing technologies, they were keen to use MJF prototypes to trial their commercial grade leaf blower before committing to injection mould tooling.

Solution

Multiple MJF prototypes were 3D printed in nylon, enabling Atom to assess fitment and visualise their design. Atom then performed vigorous testing in both wet and dry scenarios to validate their performance criteria.

Result

Atom was pleased with the full functionality MJF prototypes provided, with the parts capable of withstanding operating conditions. The models strength and performance replicated end-use parts and provided Atom with the confidence to move into production.

Key Advantages

- True assessment of fit and function

- Parts contained equal strength in the Z, X and Y dimensions

- Reduced prototyping and review process

- Reduced time-to-market and cost

Ready to speak with us?

If you have questions please feel free to contact us.

Other Case Studies.

Project Flock’s Hybrid Manufacturing Approach

Through Formero’s Hybrid Manufacturing solution, Project Flock were able to bring their innovative Biomotion tail light to market.

Read MoreQuick Turnaround Architectural Models

Using SLA we 3D Printed Architectural Models in as little as 5 days for a carbon-capture plant, which extracts CO2 from the air, directly removing CO2 from the atmosphere.

Read MoreEmirates Uses SLS 3D Printing For Supply Chain Efficiency

With a fleet of over 252 aircrafts, Emirates airlines saw cost saving opportunities through lighter weight parts, reduced inventory, and a more efficient supply chain using 3D printing technology.

Read More